TMT Water Quenching Containers: The Foundation of Contemporary Metalworking

In the realm of contemporary metallurgy, innovation and efficiency are essential, and one key component that stands out is the TMT water quenching box. This vital piece of equipment plays a significant role in the procedure of producing robust steel bars through the technique known as Thermo-Mechanical Treatment (TMT). By swiftly cooling the hot steel through water dousing, these quenching boxes ensure that the metal converts into a hardened state, enhancing its strength and efficiency for various applications in infrastructure and development.

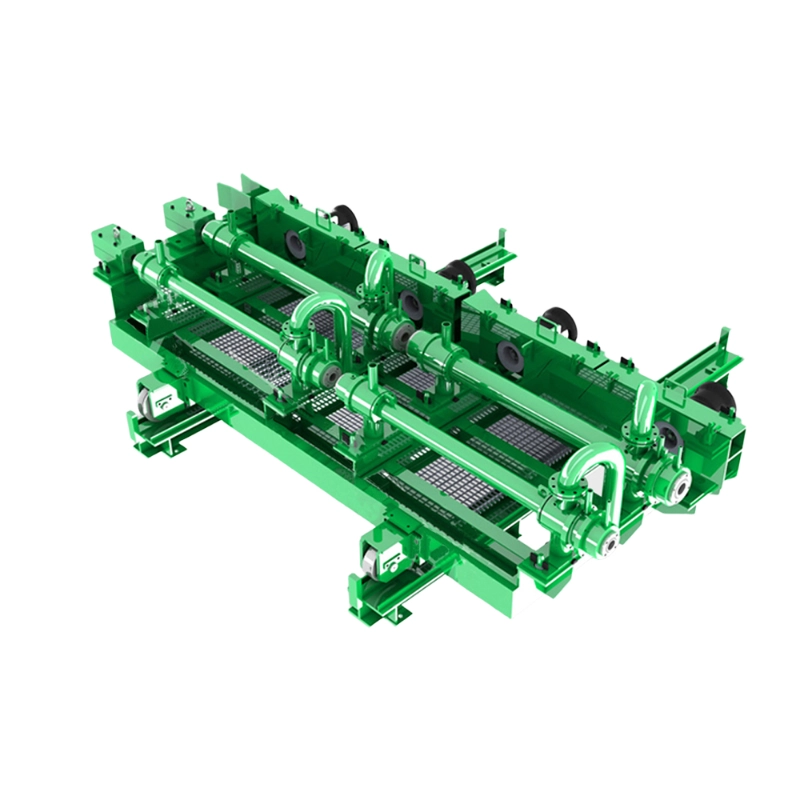

The robust TMT water quenching box is built to resist the demands of industrial environments while ensuring precision and dependability. Its ability to preserve ideal quenching conditions is essential for attaining the desired metallurgical properties in steel. Additionally, for manufacturers seeking bespoke solutions, OEM TMT water quenching boxes are available, designed to meet specific creation requirements. With advancements in technology, these boxes are turning more efficient, providing metallurgists with the tools they need to fulfill the increasing demands for superior steel in the current market.

Summary of TMT Water Quenching Technology

TMT water quenching technology plays a vital role in the metallurgy industry, specifically in the manufacturing of high-strength reinforcement bars. This process involves the swift cooling of heated steel through water quenching, which enhances the mechanical properties of the material. The change of the metal's structure during this cooling phase fundamentally influences its resilience, ductility, and toughness, making it suitable for construction and various structural applications.

At the center of this technology is the TMT water quenching box, a robust system designed to deliver even cooling across the complete surface of the metal. This ensures that each part of the steel bar is treated consistently, preventing any weak spots that could lead to weaknesses. The engineering and efficiency of these boxes are critical, as they can greatly impact output levels and overall product quality.

The requirement for high-performance steel continues to increase, making the need for reliable OEM TMT water quenching boxes more significant. Companies are increasingly emphasizing on designing advanced systems that include automation and precise control mechanisms. This not only improves the effectiveness of the quenching process but also ensures that the steel produced meets stringent industry standards and regulations. As a key component of modern metallurgy, TMT water quenching technology remains fundamental for creating durable and premium metal products.

Benefits of Robust TMT Fluid Cooling Units

Sturdy TMT water quenching units play a key role in enhancing the structural integrity of reinforced steel. By allowing quick reduction in temperature of hot steel, these units help achieve the required toughness and resilience, which are vital for many manufacturing applications. This instant cooling process ensures that the material experiences a transformation, allowing it to meet specific standards required in manufacturing and manufacturing. The improved properties result in more durable products that can endure various loads and tension.

Another significant benefit of these sturdy systems is their efficiency in the heat treatment procedure. With advanced design aspects, they optimize water utilization and improve operations, thereby cutting waste and energy consumption. This not only reduces operational costs but also contributes to eco-friendly practices in metalworking. The ability for steady performance in diverse temperatures ensures that the caliber of the steel being processed remains elevated, fostering confidence in the end product.

Additionally, a well-designed TMT fluid cooling box curbs the risk of defects such as warping or cracking during the cooling stage. By providing uniform cooling, these durable systems help manufacturers avoid unnecessary rework and product failures. As a result, operations can support enhanced throughput and improve overall output efficiency. Investing in a reliable water quenching system ultimately leads to better quality control and higher customer satisfaction in the challenging metallurgy market.

Original Equipment Manufacturer Systems for Thermo Mechanically Treated Water Quenching

In the area of metallurgy, OEM solutions play a vital role in the production of TMT water cooling boxes. These bespoke solutions are designed to meet the exact needs of metal producers, ensuring optimal performance and efficiency. By partnering with experienced OEMs, manufacturers can benefit from cutting-edge technology and designs that improve the quenching process, leading to improved mechanical properties in the final products.

One of the major advantages of opting for Original Equipment Manufacturer Thermo Mechanically Treated water cooling boxes is the ability to obtain tailored solutions that fit seamlessly into existing production lines. OEMs work closely with clients to assess their specific requirements, allowing for modifications in size, volume, and layout. This level of customization ensures that manufacturers can achieve stable quality while maximizing throughput, ultimately driving advantage in the market.

Additionally, partnering with OEMs for TMT water quenching boxes often comes with the guarantee of superior quality and reliability. These specialized suppliers employ stringent testing and quality control measures throughout their manufacturing processes. As a result, customers not only receive robust and resilient quenching systems but also ongoing support for maintenance and upgrades, making Original Equipment Manufacturer systems a smart investment for modern metallurgical operations.

https://www.ahhfsnyj.com/category/products/tmt-water-quenching-box/